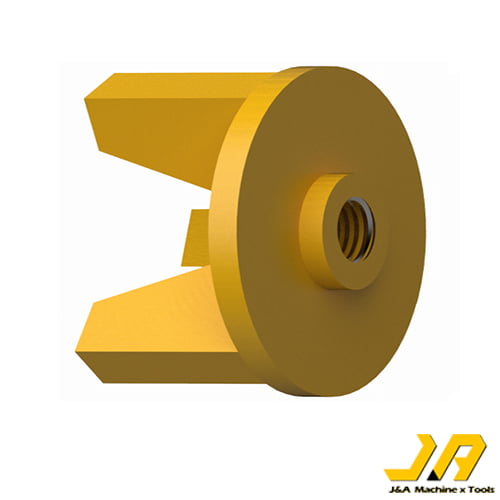

Water pump fan blades are an integral part of our water supply and drainage systems. Common fan blade manufacturing processes are divided into welding and casting.

We use high-quality carbon steel to welding fan blade manufacturing, laser cutting and blanking, no burrs and no deformation in the incision; through special positioning tooling, insert the parts and plates of the fan blade, lock the positioning groove, and perform assembly spot welding firmly to ensure uniformity Specifications and dimensions; the inch thread interface is pre-processed; after assembly, a fully automated welding manipulator is used to form a ring weld, and the threaded mandrel is in the welding process to ensure that the thread will not be deformed due to the influence of welding heat efficiency.

After welding, grind and clean the surface of the workpiece, and check the appearance, weld seam, threaded joint and other dimensions of the product one by one to ensure the quality of product delivery.

Welded fan blades have the advantages of beautiful appearance, high strength, not fragile, and easy to replace.

After all you can always trust JA Gold Equipment.