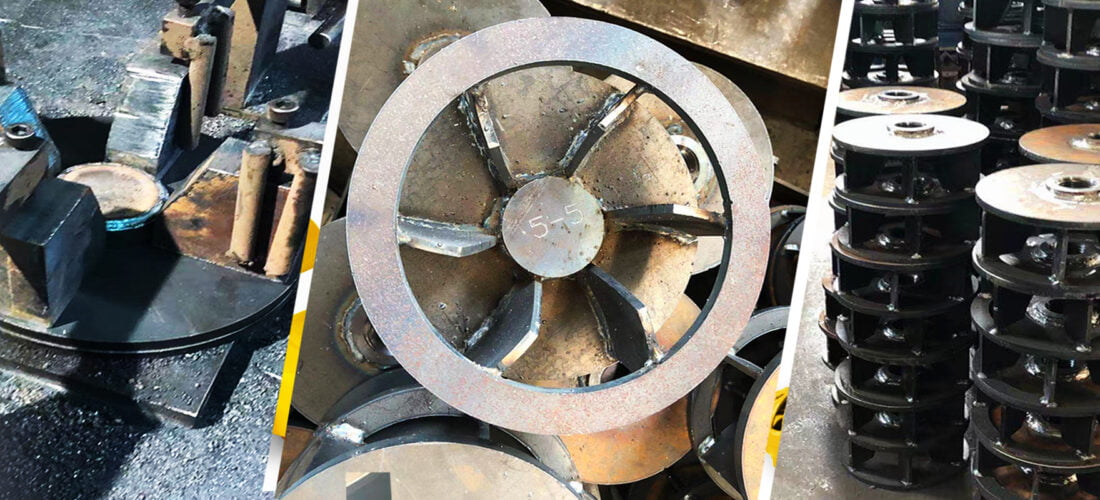

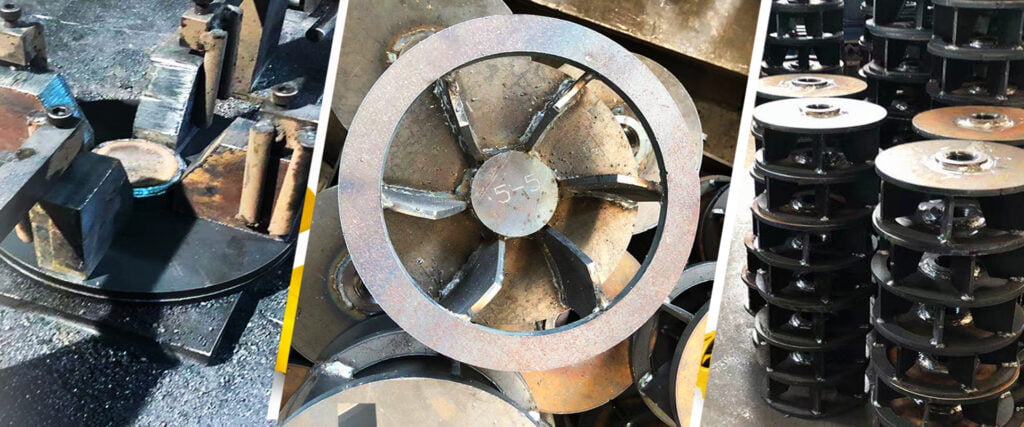

Introduction to JA’s casting process

Casting technology is widely used in the production of our products. The common ones are HT (gray cast iron) and QT (nodular cast iron); the appropriate grade can be selected according to different working conditions.

HT gray cast iron characteristics: low tensile strength and plasticity, but good casting performance and shock absorption performance, mainly used to cast pressure and vibration parts such as bases, end covers, floor drains, etc.;

QT ductile iron features: medium strength and toughness, good machinability; wide range of uses, such as water pump casing, water pump blade, drive shaft, etc.

Casting process: pig iron is the main raw material, and auxiliary materials such as ferrosilicon, ferromanganese, and recarburizer are added; if it is QT ductile iron, a certain amount of nodularizer is required, and carbon and silicon are added; in the intermediate frequency electric furnace, HT Heating: 1460-1480 degrees, QT heating 1480-1530 degrees to make it completely melted, we use special prefabricated molds for pouring, after cooling, grinding and sand washing to obtain the product shape we need.

Our products are basically QT ductile iron, quality assurance, it is worth choosing.

check the link to see more casting products

https://goldequipment.com.br/product-category/brazil-gold-rush-components/